MCES delivers on time and on budget by providing unmatched standards in a complete range of electrical and instrumentation services. Our carefully curated network of electricians, instrument technicians, and product specialists are renowned in their efficiency and discipline, providing the results that have brought us to where we are today.

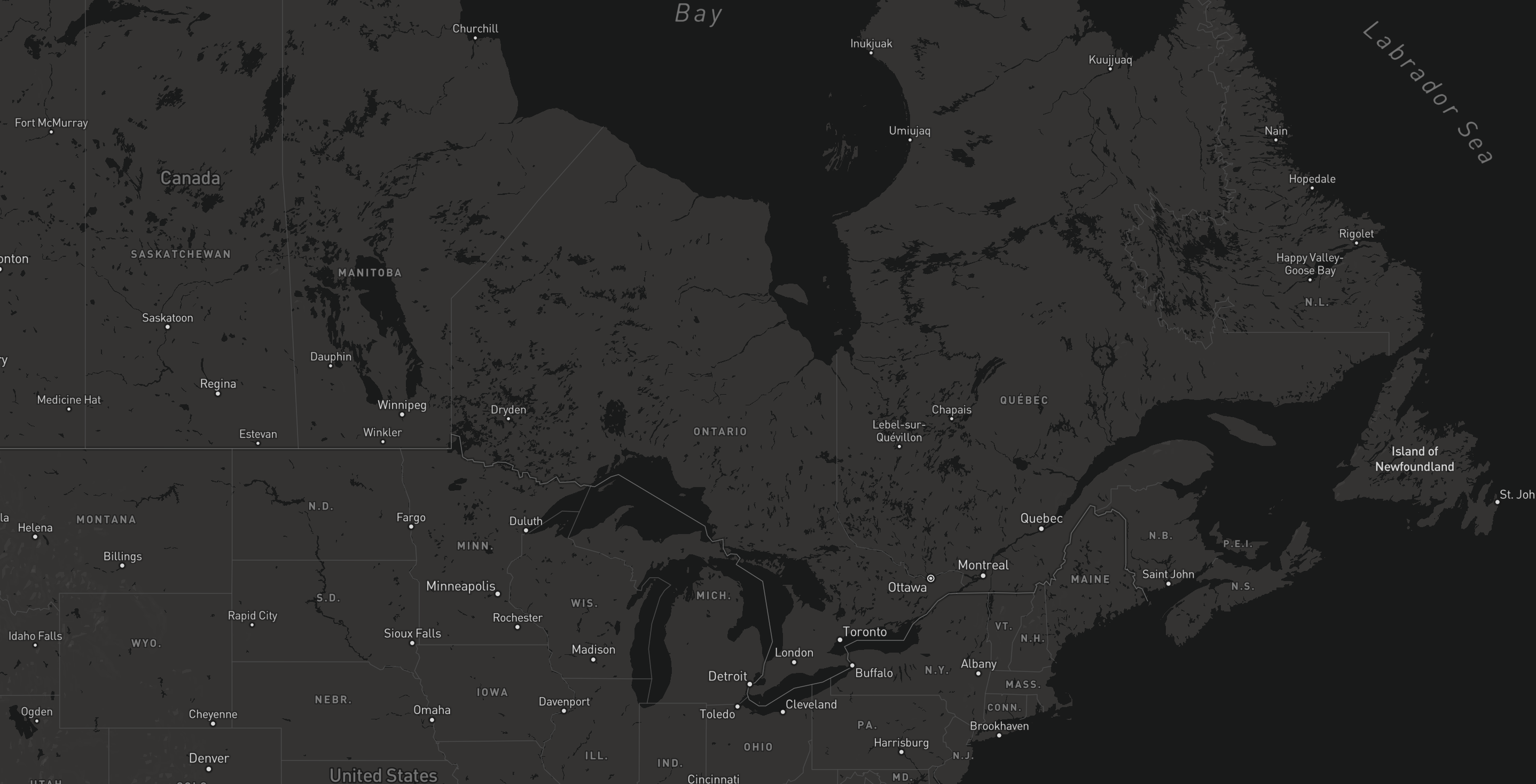

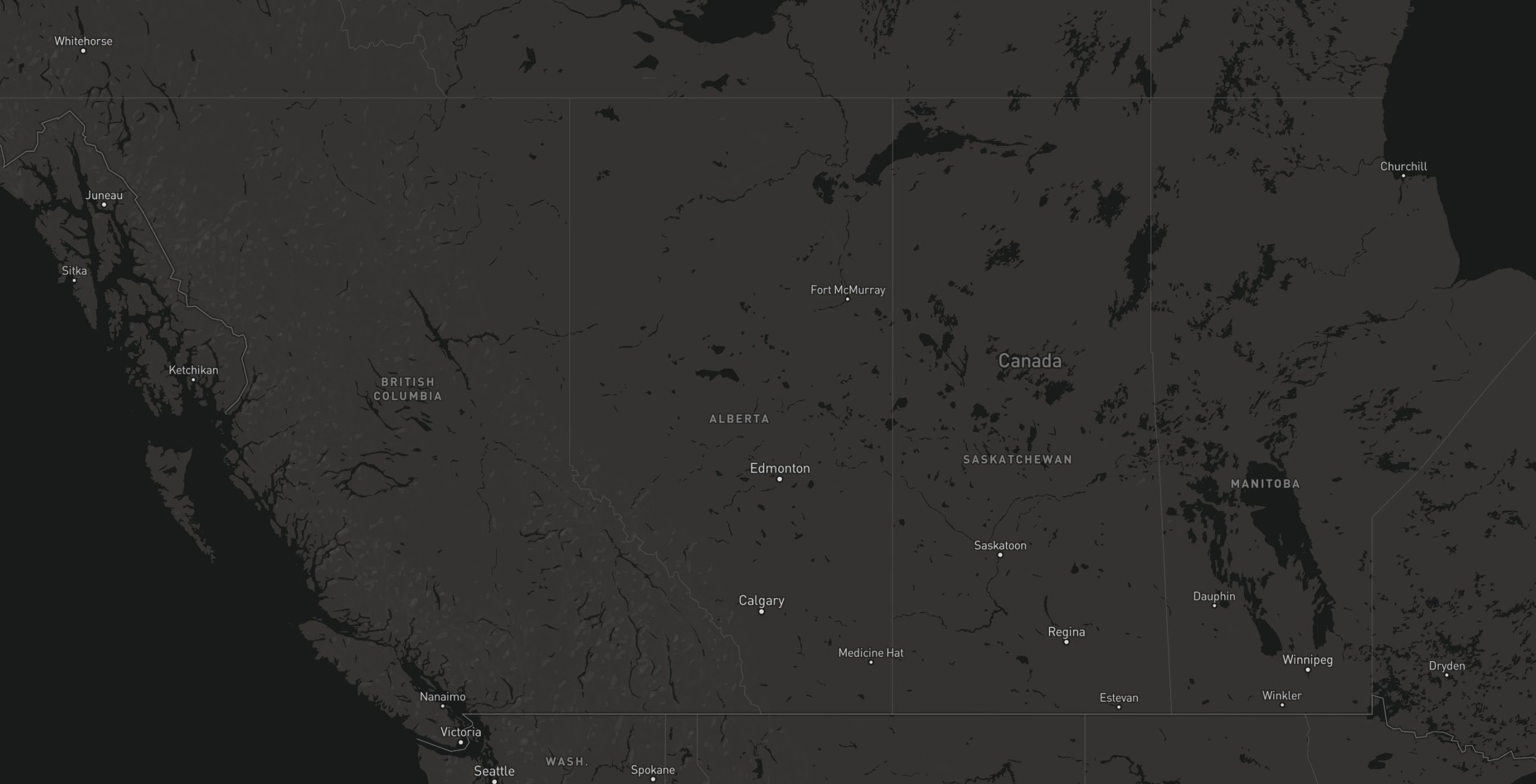

Learn more about our projects by clicking on the map.

Teck Coal

Fording River Saturated Rock Fill Pre-Commissioning

Successfully provided construction management, turnover assistance, and pre-commissioning through inspection of all instrument installations, QC checks of instruments, and calibration of all devices on site. Also performed commissioning and startup assistance.

Suncor

Fort Hills

Successful construction of OPP Dry (Crushing Plant) with installation of all instruments as well as QC of all instruments. Also coordinated with field techs to test devices and completed all reporting, forecasting. Also supported Suncor team for pre-commissioning, commissioning and start-up.

K+S

Legacy Potash Mine

Successful construction and rebuild of Areas 2421 and 2560. Project included the receiving, inspection, and installation of all instruments and mounting brackets as well instrument preservation, inventory and quality assurance. Also performed TSASK Certified pressure testing of all tubing for cooling towers and pump houses.

Village of Alix

Main Street Lift Station

Completed new construction of the lift station, including the installation of new electrical service, new generator and transfer switch, new PLC, and new soft-starts for motor control and sampling unit. Also performed full commission for lift station.

Shell Canada

Kaybob Facility

Successful pre-commissioning and commissioning through calibration of all instrumentation, function testing of plant systems, and plant startup and operations assistance to ensure smooth transition from construction to operations.

Trans Canada Pipeline

Keystone XL Pump Stations

Successful commissioning and PLC upgrades. Updated programming in the station PLC for each pump station, tested all instrumentation and electrical back to the PLC, ensured proper bypasses were in place and completed all upgrades and removed all bypasses to ensure pump station was back to normal operating conditions.

Husky Sunrise

CPF Phase 1

Completed instrumentation and electrical construction management, QA and QC, and commissioning of the LACT. Also coordinated with field techs to test devices and ensure a smooth commissioning and startup.

IG Machine & Fibres

Installed a new PLC, set up a plant time clock, set up automated start timers for all equipment, and function tested all automated start-up systems. Also designed and installed a soft start system for the fan motors of the tempered water unit.